Mixing machine has become the preferred mixing equipment of many rubber and plastic enterprises because of its advantages of large mixing capacity, small environmental pollution and so on. With the continuous development of production and application of mixing machine, mixing mode is showing a development from shearing type to

kneading type, and kneading mixer is gradually being accepted by the industry. Kneading mixer plays an important role in the feed production of powder injection molding industry.

Ordinary mixer machine mainly by the rotor, short edge peak four edges and mixing interior wall shear force of

relative to shear of material, material evenly done between length edge peak and then achieve the purpose of

mixing, the filling coefficient of the device is bigger, though short mixing time, production is high, but the material

of shear force is too large, warming faster, The spray cooling method of rotor is less efficient and can not achieve

the purpose of cooling quickly.

And kneading mixer to relative peak due to the length of the rotor is rotating, the material can be packed into the

rotor's edge peak between mixing and kneading filling coefficient is small, the material rising slowly, and the rotor

internal USES is mandatory cooling water cooling, cooling rapidly, whether for rubber or warming faster metal

powder is a good thing, Therefore kneading mixer is also used by MIM industry feed suppliers for metal feed

production.

Another improvement of kneading mixer is that the surface in direct contact with the material is welded hard alloy.

Besides surfacing hard alloy, chrome plating is also used for the special metal design to increase its wear

resistance and corrosion resistance. In addition, the kneading mixer generally adopts hydraulic upper plug, which

can exert constant pressure on the mixing material and improve the mixing effect. The advantages of the upper

plug device also include convenient loading and unloading, which can save the time of cleaning the mixing

chamber.

Kneading mixer adopts hydraulic seal, a layer of sealing oil film will be formed on the sealing surface, not only the

sealing effect is good, but also the sealing structure is simple, and the disassembly and replacement of sealing ring

are more convenient. Although kneading mixer has the disadvantage of small effective mixing volume and small

mixing output, it can be made up by increasing the rotating speed because of its good material cooling

performance. Kneading mixer inherits a series of advantages of mixer from the beginning of its birth, and has

different degrees of improvement on this basis. In the future, kneading mixer will replace the traditional shear

mixer and become the leading mixer in the market.

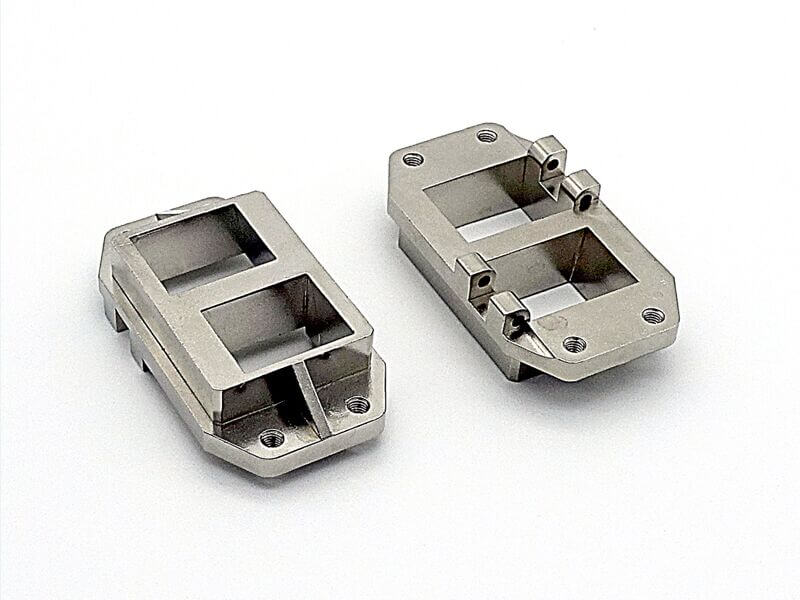

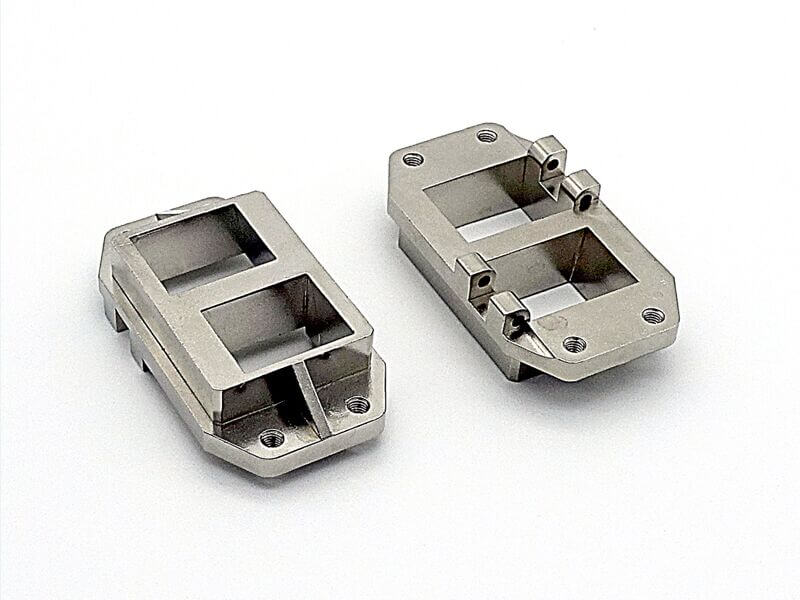

Stainless steel cnc machining parts China Metal Parts Services - CNC Machining Parts Supplier

World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More

Stainless steel cnc machining parts China Metal Parts Services - CNC Machining Parts Supplier

World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More  customized metal board cnc parts OEM Custom Cnc Milling Turning Stainless Steel Aluminum Brass Metal Parts More

customized metal board cnc parts OEM Custom Cnc Milling Turning Stainless Steel Aluminum Brass Metal Parts More  electric motorcycle cnc milling turning metal parts Custom CNC turning milling machining aluminum service More

electric motorcycle cnc milling turning metal parts Custom CNC turning milling machining aluminum service More  Precision Cnc Turning Milling Machining Atv/Utv Parts & Accessories Precision Cnc Turning Milling Machining Atv/Utv Parts & Accessories More

Precision Cnc Turning Milling Machining Atv/Utv Parts & Accessories Precision Cnc Turning Milling Machining Atv/Utv Parts & Accessories More  the head of custom spray gun Custom CNC Machining Service Precision Titanium Brass Stainless Steel More

the head of custom spray gun Custom CNC Machining Service Precision Titanium Brass Stainless Steel More  CNC Machining Parts Manufacturer Stainless Steel Aluminum CNC Mechanical Parts Precision CNC Turning Steel Parts ,CNC Machine Part More

CNC Machining Parts Manufacturer Stainless Steel Aluminum CNC Mechanical Parts Precision CNC Turning Steel Parts ,CNC Machine Part More  cnc milling machining turning spare parts mechanical parts China Metal Parts Services - CNC Machining Parts Supplier World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More

cnc milling machining turning spare parts mechanical parts China Metal Parts Services - CNC Machining Parts Supplier World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More  CNC Machining Precision Parts Full Shift Switch Invisible Switch China Metal Parts Services - CNC Machining Parts Supplier World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More

CNC Machining Precision Parts Full Shift Switch Invisible Switch China Metal Parts Services - CNC Machining Parts Supplier World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More  CNC machining small aluminum machined metal wheel gear parts China Metal Parts Services - CNC Machining Parts Supplier World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More

CNC machining small aluminum machined metal wheel gear parts China Metal Parts Services - CNC Machining Parts Supplier World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More  the customized metal parts of toy model car wheel hub we are specialized in prodicing all kinds of metal parts applying to building Material Shops, Manufacturing plant, and so forth so on More

the customized metal parts of toy model car wheel hub we are specialized in prodicing all kinds of metal parts applying to building Material Shops, Manufacturing plant, and so forth so on More  High Precision Parts Cnc Turning Machining Aluminum OEM ODM CNC Drilling Milling Machining Service We provide CNC drilling services that can process small and large batches of components of any complexity. We use different types of drilling machines (vertical, bench, radial) to drill holes with a diameter of up to 7 centimeters, and can achieve simple or complex patterns. This manufacturing method is applicable to metals and alloys (aluminum, steel, copper, etc.) and polymers More

High Precision Parts Cnc Turning Machining Aluminum OEM ODM CNC Drilling Milling Machining Service We provide CNC drilling services that can process small and large batches of components of any complexity. We use different types of drilling machines (vertical, bench, radial) to drill holes with a diameter of up to 7 centimeters, and can achieve simple or complex patterns. This manufacturing method is applicable to metals and alloys (aluminum, steel, copper, etc.) and polymers More  High Precision Parts Cnc Turning Machining Aluminum OEM ODM CNC Drilling Milling Machining Service china manufacturer professional made precision profile aluminum swiss machining cnc drilling parts More

High Precision Parts Cnc Turning Machining Aluminum OEM ODM CNC Drilling Milling Machining Service china manufacturer professional made precision profile aluminum swiss machining cnc drilling parts More  Customized Pen Shell we provide CNC machining service,just sending us a drawing for quote. More

Customized Pen Shell we provide CNC machining service,just sending us a drawing for quote. More  the shell of portable battery ,the customized metal housing sent us the drawings and we give you a appropriate quote More

the shell of portable battery ,the customized metal housing sent us the drawings and we give you a appropriate quote More  the metal cap of pen ,none-standard cap we are chinese manufacturer ,we provide competetive price.we can produce CNC parts and make a polishing. More

the metal cap of pen ,none-standard cap we are chinese manufacturer ,we provide competetive price.we can produce CNC parts and make a polishing. More  What principles should be followed in the arrangement of CNC machining sequence? More

What principles should be followed in the arrangement of CNC machining sequence? More  Technology Application For CNC More

Technology Application For CNC More  Basic composition of CNC lathe More

Basic composition of CNC lathe More  Selection principles for CNC More

Selection principles for CNC More  The Fetures Of CNC More

The Fetures Of CNC More  CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More

CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More  CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More

CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More  CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More

CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More  CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More

CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More  CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More

CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More  CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More

CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More